Engineering Projects

Welcome to my engineering portfolio! Here, you’ll find a collection of my projects and experiences, including my work at Ballard. Each project was a unique challenge and an opportunity for growth.

Ballard Power Systems 70kW Test Cart Internship Project

Internship Role: Electrical Engineer

-

Purpose: Designed and assembled a 70kW test cart to assist in troubleshooting and testing for the team.

-

Electrical Setup: Installed a 35A fuse for high-voltage protection, safeguarding the system against overcurrent scenarios.

-

Power Distribution: Organized wiring into positive and negative sections using 10 AWG wire, ensuring stable power flow.

-

Component Integration: A 36V, 40A power supply was used to power the entire setup, ensuring reliability.

-

Mechanical Work: Utilized tools like a Dremel and drill for mounting and assembly tasks, including drilling holes for custom mounts.

-

Functional I/O Check: Utilized digital multimeters (DMMs) for precise continuity testing and oscilloscopes for in-depth signal analysis on faulty or misaligned valves.

-

3D Modelling: Utilized AUTOCAD and Tinker Cad to create cart design and custom mounts for electronic parts.

-

Team Collaboration: Worked closely with team members to refine the design and implementation, ensuring the cart met project requirements.

Fig#1: Final design and dimensions of cart.

Fig#2: Measuring PWM Signal for one of the valves.

Fig#3: AutoCAD PDB Enclosure Mount Design

CSIS Project

EMC/EMI Shielding Spray

Intership Role: Electrical Engineer

Fig#1: Our mitigation proposal.

Fig#2: Short video of of implementation.

-

Team Achievement: Won 1st place in the CSIS competition at Ballard Power Systems.

-

Award Received: Honored with the Shanna Knights Award for the "farthest out-of-the-box idea that was well-considered, where risk is valued and success or failure is not a criterion."

-

Tools and Equipment: Utilized a spectrum analyzer to measure electromagnetic interference (EMI), employed a BCI (Bulk Current Injection) cart to generate EMI noise, and used an antenna probe to capture and analyze signals with the spectrum analyzer.

-

Project Focus: Addressed the issue of electromagnetic interference (EMI) in electronic systems where an electronic system can act like an antenna and generate an electromagnetic field.

-

Innovation: Integrated an EMC shielding spray to mitigate noise emitted by electronic components.

-

Technical Approach: Applied noise of 90Mhz and current intensity of 100mA Applied conductive spray to reduce electromagnetic interference (EMC) and create a larger attenuation.

-

Team Impact: The project contributed to a more robust, noise-resistant design, showcasing innovation and efficiency.

Fig#3: Signal dropping due to ESD.

Electrostatic Discharge (ESD) Mitigation and Troubleshooting

Intership Role: Electrical Engineer

-

Purpose: To manage static discharge buildup that could potentially damage the surrounding electronic components of a module.

-

Tools and Equipment: ESD measuring meter to detect high static discharge areas, and oscilloscopes to monitor ESD buildup and signal fluctuations at 250 nanoseconds.

-

Implementation Against ESD: Ground electronic components to the chassis and apply conductive tape(aluminum tape) around the plastic enclosures to ensure proper grounding.

Fig#1: ESD causing electronic interference.

Fig#2: Video of oscilloscope capturing the ESD.

Fig#3:Measuring over 1000V of ESD.

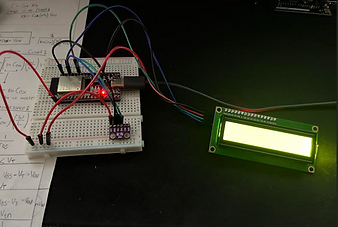

BMP280 Sensor Integration of ESP32

-

Purpose: Develop an affordable weather monitoring system using BMP280 and ESP32, making technology accessible for people in third-world countries who cannot afford expensive weather stations.

-

Hardware & Software: Used ESP32-WROOM-32D, BMP280 sensor, LCD1602 I2C module, programmed with Arduino IDE, Adafruit BMP280 Library, and CP2102 driver.

-

Used software Fritz to create breadboard layouts

-

-

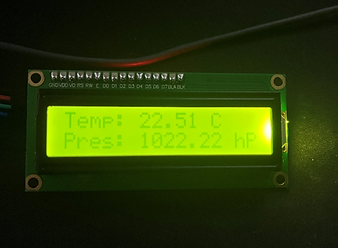

Implementation: Integrated BMP280 via I2C (GPIO 21 & 22), displayed real-time data on LCD1602, and verified functionality using Serial Monitor in Arduino IDE.

-

Applications: The system is ideal for rural areas, remote farms, and disaster-prone regions, providing real-time weather data to support agriculture, disaster preparedness, and local forecasting.

-

Scalability: Can be expanded with humidity sensors, cloud data storage, and mobile app integration to enhance usability and real-time remote monitoring.

Fig#1: BreadBoard Layout of ESP 32+BMP280+LCD

Fig#2:Displayed Temperature and Pressure Reading's